How to Build Drawers for your Van

High Quality Drawer Boxes for your Van

Proper woodworking requires proper tools. We do not own a table saw and we have no way to make dovetailed joints. However, we came up with a great way to make very high quality drawer boxes with only a cheap circular saw and a screwdriver. The drawer boxes are offered as a bolt-together kit by Blum, a premium Austrian hardware manufacturer.

Why Blum Drawer Boxes?

We chose these drawer boxes for their high quality, ease of assembly and wide range of adjustability. Because most vans are going to have odd-sized drawers, this kit will allow you to easily create a drawer of any size. For the less-precise van builder, these drawers also allow you to adjust the drawer face up and down, side to side, or tilt it in order to allow for perfect drawer alignment. I can’t stress how much this aids in creating a very professional end-product.

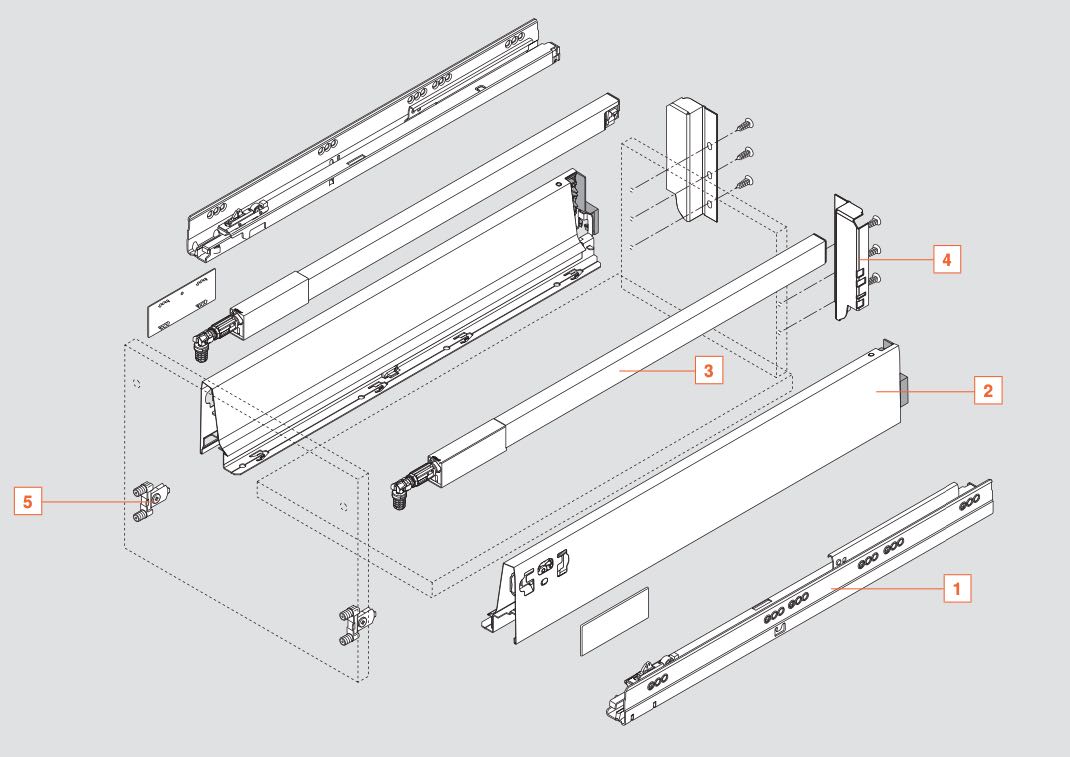

Drawer Kit Components

This kit has four or five components, shown in the photo below. Component (1) is the “cabinet profile” or drawer slides with integrated soft-close. Component (2) is the “drawer profile,” or the drawer box. Part (3) is the optional “gallery rod” that can be used in deep drawers. These extend the height of the side of the drawers while maintaining the ability for the fine-tune adjustment of the drawer front. Only our bottom two deeper drawers utilize gallery rods. Components (4) and (5) are rear and front “fixing brackets,” respectively, to attach the drawer front and back to the drawer box.

Note: This site contains affiliate links for which I may be compensated.

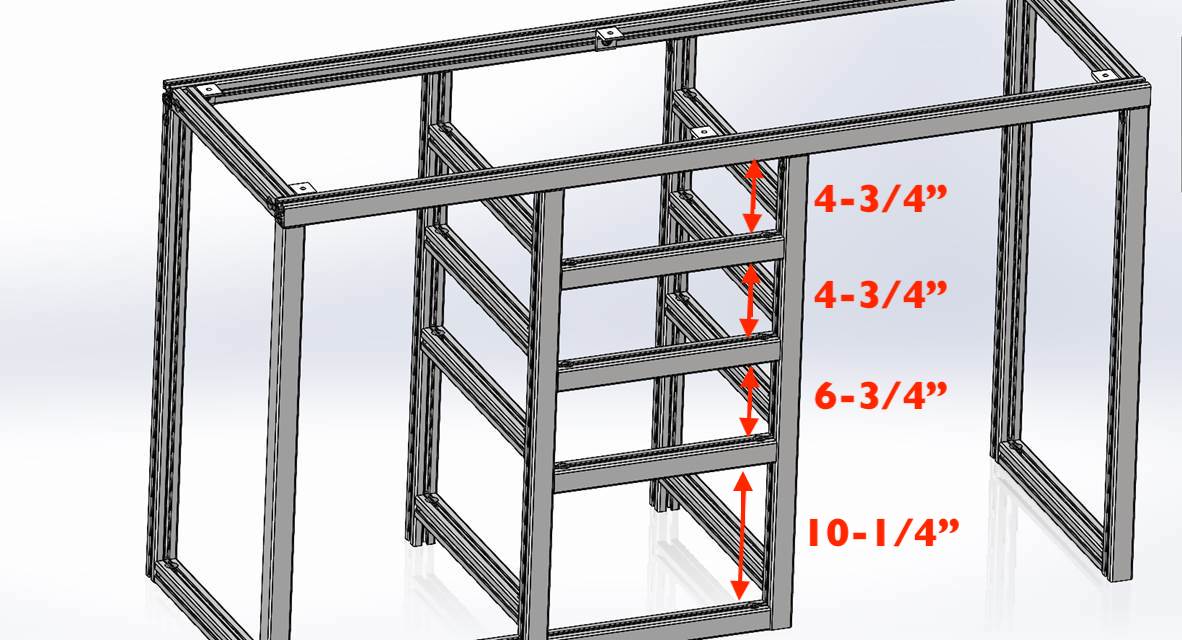

Here’s the often misunderstood detail, the drawer box, drawer slides and front fixing brackets are all the same, regardless of drawer depth. It’s the height of the REAR FIXING BRACKET that affects the depth of the drawer. The drawer sides are 3-5/16″ tall. For our upper two small drawers we are using the standard-height rear fixing brackets and no gallery rod. Our third drawer down uses the medium-sized rear fixing bracket with a gallery rod. This creates 5-3/4″ deep drawer. Finally, our fourth and final drawer down uses the larger rear fixing bracket with gallery rod, creating a 8-1/4″ deep drawer. You can see the different drawer depths in the photo.

Drawer Sizing

The drawers can be made most any width, however the drawer length is determined by the depth of your cabinet. Let’s say you are purchasing the OurKaravan Galley Framing Kit–the galley is 22″ deep and thus 22″ drawers can be used. (This assumes of course that you have nothing additional mounted to the wall behind the cabinet.)

If you want to replicate the setup you see here, you would order (4) 22-inch drawer boxes, (4) 22-inch drawer slides, (4) sets of front fixing brackets, (2) sets of 3-5/8″ rear fixing brackets, (1) set of 5-3/4″ rear fixing brackets, (1) set of 8-1/4″ rear fixing brackets, and (2) sets of gallery rods for those two deeper drawers.

*Please note that our drawers are stainless steel, which is no longer available. The same kits are still available in gray.

Parts Required

- Blum Drawer Box or “Drawer Profile” (we use 22-inch)

- Soft-Close Drawer Slides “Cabinet Profile” (we use 22-inch)

- Front Fixing Brackets (requires two per drawer) [one-size fits all]

- Rear Fixing Brackets (pair): 3-5/8″ deep | 5-3/4″ deep | 8-1/4″ deep

- Optional Pair of Galley Rods (21-5/8″ for 22″ deep drawers)

Other Required Parts

- 80/20 M4 Roll-in T-nuts (for securing the drawer slide to the 80/20 framing)

- M4 x 12mm bolts (0.7 pitch to bolt the drawer slide to the framing)

- 1/2″ or 5/8″ plywood

- #6 1/2″ wood screws

Before we dive-in, you may want to watch our YouTube video as a project overview.

Building the Drawer Bottoms

As a frame of reference, the measurements below show the spacing of our drawer laterals. This determines the depth of the drawers.

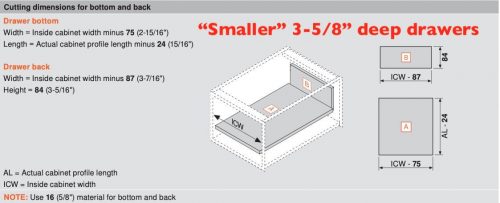

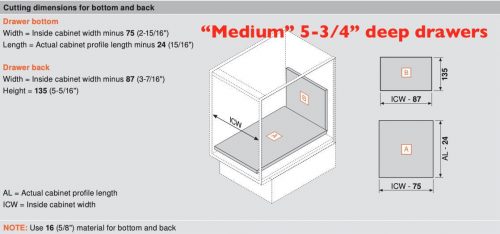

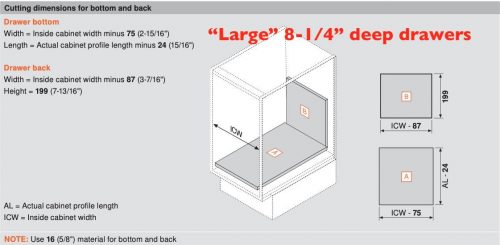

Keep in mind, all of the drawers will use the same bottoms. To create the drawer bottom we need to measure the width of our drawer opening. If you’re using our OurKaravan galley, that measurement is 15-inches. Take that dimension and subtract a fixed 2-15/16 inches, which comes out to 12-1/16 inches. This is how wide you cut your plywood.

The length of the drawer bottom is the cabinet profile length (in this case 22 inches), subtract a fixed 15/16 inches, which comes out to 21-1/16 inches. This is the length of your drawer bottom. In the case of our galley, all four bottoms would be cut to the exact same dimension. (12-1/16″ x 21-1/16″) Only the drawer backs differ, and when combined with the gallery rod, create the depth of the drawer.

Building the Drawer Backs

All drawers will use the same dimension for the WIDTH of the drawer back. Take the inside cabinet width and subtract 3-7/16 inches. In this case, 15 inches minus 3-7/16 inches is 11-9/16 inches. All four (in our case) drawer backs will be 11-9/16 inches wide.

Putting the Drawer Boxes Together

Gallery Rods for Deeper Drawers

On the deeper drawers, the gallery rod simply clicks into place on the rear fixing plate. (Video timestamp: 8:23). Later when we make the drawer faceplates, the other end will insert into a hole in the back of the faceplate.

Mounting the Drawer Slides

If you are mounting your drawer slides to 80/20 profiles, follow these steps. I find it easiest to use 80/20 Roll-in T-nuts to snap into the t-slotted profile. You may want to use three per side, with them spread out to support the front, middle and rear of the slide. The specifications from Blum indicate you want the drawer slide to mount 33 millimeters off the bottom of the drawer. If using our 80/20 galley cabinet, loosen the fasteners and raise the 80/20 profile so it sits 33mm off the profile that runs across the front of the drawer opening. (Video timestamp: 9:14)

With about three roll-in t-nuts inserted per side, pass the M4 bolts through the holes in the drawer slide and into the t-nut in the aluminum profile. At 12:33 we share a little tip regarding aligning the t-nuts with the holes–basically don’t even try. Pop the t-nuts in and if you keep everything loose you can slide the profile back and forth to align it with the t-nuts.

Install the Drawers

You can install the drawers but aligning it with the track and pushing the drawer back. When it comes time to install the drawer faces, we popped the front fixing plates into place in the front of the drawers. We then put grease on the ends of the fixing plates, aligned our drawers and pressed them up against the fixing plate to mark where to drill the holes. Then use two screws per fixing plate and attach them to the drawer face. This process is probably best viewed by watching our video on creating drawer faces and cabinet fronts.

The gallery rods require a 10mm hole 1/2″ deep. If you’re using 1/2″ plywood, be very careful here as you don’t want to drill-through…I would drill 3/8″ deep and epoxy the end of the gallery rod in place if you have to. Place the hole such that the gallery rod is straight and level with the main drawer box.

You now have custom Austrian-made soft-close van drawers, congratulations!

Content Creation

We are doing our best to offer as much information as possible for free. A lot of time, effort and money goes into developing and maintaining this website. If you find the information on this website helpful, you may use our various links when you are ready to make purchases. As Amazon Associates we will make earnings from qualifying purchases, however it costs you nothing to use them. Alternatively you may consider using the donate button below to make a simple Paypal payment, or message us if you prefer Venmo. We sincerely appreciate your visit as well as your support.

Hello,

Will you build me a set of drawers? I am buying a overland trailer and need to have five Zarges boxes in pull out of a frame. The K9 AluBox Mount is a quick disconnect that I would like to add to the sliding drawers.

Hi, I appreciate the offer but unfortunately I’m pretty tied up with work at the moment. The Blum drawer boxes are pretty straight-forward to assemble if you’re willing to give it a go. -Ken

Hey Ken!

One question if I may:

Above you mention “the galley is 22″ deep and thus 22″ drawers can be used.”

However, in your 80/20 3D Sketchup model, the galley is 20″ deep, and in your Van Drawers video, you mention actually using 18″ slides because you don’t have quite the depth to use 20″ slides.

I am in the process of building my galley and I am a bit confused by the information.

Thank you for all the great content btw 🙂

You have that correct, my galley is 20″ deep because I needed room for my sliding second row seat to be able to fit between the galley and the side of the van. I also have electrical distribution panels behind my gallery drawers, which means I don’t have the full depth available to me.

The pre-cut galley is 22″ deep and as long as you have nothing mounted to the van wall directly behind the drawers, you can use the 22″ length. You can also shorten the cut for the drawer bottom to whatever you like but there is room for a 22″ drawer on the pre-cut galley. -Ken

Excellent stuff, as always 🙂 Cheers!

I’m having trouble finding a link to where you purchased or how you built the drawer fronts. The video linked shows how to mount the drawers but not where they are from, the video mentions checking out your store but I don’t see them there either LOL – can you help? How did you make/buy the drawer fronts?

Hi Jaime, correct, this article is how to build drawers. If you look in the “parts required” section of this article you’ll find links to buy them.

I don’t have a write-up yet on making the drawer fronts, but I do have a video on it: https://www.youtube.com/watch?v=_RccPYPiTkE

I hope that helps!

Ken

Hi Ken,

As always, thank you for taking time to put this together and for sharing this! I have a question if you happen to have time to answer. Since the stainless steel Tandembox drawer profile has been discontinued, do you think I would be able to go with the Legrabox profile which comes with the stainless steel version and still stay within the drawer measurements above? But I understand that the Legrabox won’t have the gallery rod look and feel which I do like.

Cheers,

KP

Hi KP, I looked it up and it looks similar in design. I haven’t built one but I see it as a viable option. The SS is very nice. -Ken

All Tandembox is discontinued.

EB Bradley (wholesale only but they will direct you to a local supplier) suggested switching to Legrabox. Unfortunately drawer bottom requires a rabbet joint which is beyond our skill level. If you are going this direction, EB Bradley has kits in their catalog for easy ordering.

https://ad.wpcappserve.com/cust/ebbradley/pdf/catalog/2018/EBB_Vol25_Catalog_S02_Drawer_Slides_&_Box_Systems.pdf

pages 185-191

Metabox seems insubstantial but may use as these drawers won’t be heavily loaded.

They still manufacture Tandembox, just not in stainless. See my article and links here: https://ourkaravan.com/building-drawers/

Hello! Concerning the 8020 running across the front of the drawer opening, in between each cabinet – are those necessary? Do they support some weight of the drawer, or just cosmetic? Thank you!

Hi, the main purpose is to provide a place to mount the catch for the slam latches. Without these cross bars the drawer has no way to lock in the closed position.

I note that in your vertical stack-up of drawers and cross bars there are 5 cross bars. They total 7.5 inch of vertical, unusable space. Thats approaching 25% of the total stack-up. Is the loose of one drawer of storage capacity worth the gain of those snazzy latches you have sourced? Admittedly I have the benefit of hind site gained by reviewing your excellent material so please take no offense as none is intended. I ask your opinion of utilizing an alternative design; a latch that engages on the side, eliminating the horizontal runners in the front. and adding intermediate vertical members along the sides to obtain 4 mounting points for each slide. My installation is in a trailer with an OEM supplied metal counter that is very robust as is the floor. In addition I would enclose the sides and back side of the cabinet with panels to gain shear strength, to help prevent racking, and for dust control. Do you see any reason why this approach would not work?

Again, thanks for putting together this information. It is very helpful and the presentation topnotch!

Hi Peter,

Thank you for the kind words. The top and bottom cross bars are necessary to join the structure. However you’re correct that there are three cross bars (total of 4.5″) where there’s room for a gain in space efficiency. I could have used half profiles in these locations however it adds yet another profile type to the construction and you would be required to use anchor fasteners as there would be no slot to hide angle brackets. I’ve tried using magnets to hold drawers closed, which is not a good solution–so slam latches are all that I would use. You could probably put a slam latch on one side of the drawer to eliminate three cross bars, but the aesthetic may not be pleasing. Let us know what you come up with! -Ken

Do you have the dimensions for the drawer faces? I purchased your kit from Heitek Automation and am trying to build to your dimensions.

Thank you.

Hi, I can provide any dimension you like, just know it would likely be easier to measure off your galley and decide exactly how much gap you want between each drawer and cabinet door. Any slight variation in, say, the mounting of the hinge on the cabinet door, would result in an unaccounted-for gap somewhere else. My contact info is on this site if you’d like more info, I’m always happy to help. -Ken

Ken,

Thank you so much for your videos. My drawers are turning out perfect.

Barb

Thank you, I appreciate the feedback! We love ours. -Ken

I love those floors. Where did you get them?

I purchased it from a local Carpet One near me. It’s Earthscapes brand, Pajero 591 style. I love it. -Ken

Hi Ken!

I want to build your exact drawers but when I click on the Amazon link it says the Blum products are unavailable.. any recommendations on a different brand or thoughts on Blums new under mount drawer design? Thanks!

Carissa Rasmussen

Hi Carissa, with all of the supply chain problems these go in and out of stock regularly, as do a lot of other products. You might search the web and see if another vendor has them in stock. It pretty much changes by the day. Take care! -Ken

Started this weekend! Thanks for taking the time to answer my emails. We cut out the drawer bottoms and backs this afternoon with a skill-saw. Not perfect and hoping that our little mistakes aren’t big ones.

Waiting for the Blum drawers to come in.

My van was built with caveman tools so it can be done. Congrats on completing that project! -Ken

Where did you order the bamboo faces and door?

I purchased the bamboo from both Hughes Hardwoods in Rancho Cordova, CA and Auburn Hardwoods in Auburn, CA. Neither store had any trouble ordering it, so based on that I would think most good hardwood stores could obtain it for you.

Hi there, Much of the hardware you link to is no longer available. I’m ordering your pre-fab galley through hietek so I want to make sure I order the correct hardware that will be compatible. Any way to update your links with the current Blum products available? I’d be happy to use your Amazon Associate links… Thank you!

Thanks, Ken! I greatly appreciate this resource you’ve created!

Stella, links have been updated, thanks for letting me know! -Ken

Hey Ken,

How the heck did you attach the catches for the slam latch to the 8020?

Tap threads and use little bolts? I can’t figure it out. Thansk! – Henry

Hi Henry, check out this video for details: https://www.youtube.com/watch?v=Kqhg02EIHNc

-Ken

Thanks Ken, I watched the video. I am shooting for inset drawer faces which makes the dimensions for catch install

a hard lift; I got a deeper button and the catch/latch fits like a glove. Thanks!

Awesome, thanks for reporting back! -Ken

Much appreciation for your willingness to share your hard work, research, and details from your van build- it has simplified my own build significantly. I noticed while watching the Youtube video for these drawer boxes, that it appeared you were using a ratcheting allen wrench. Could you share a model number or a link to where I could order one? Thanks again for the ideas, details, and inspiration from your beautiful build!

Hi Jason, I don’t have any ratcheting Allen wrenches but I do have a Craftsman Allen socket set that works with a 3/8″ standard ratchet. Thank you for your kind words! -Ken